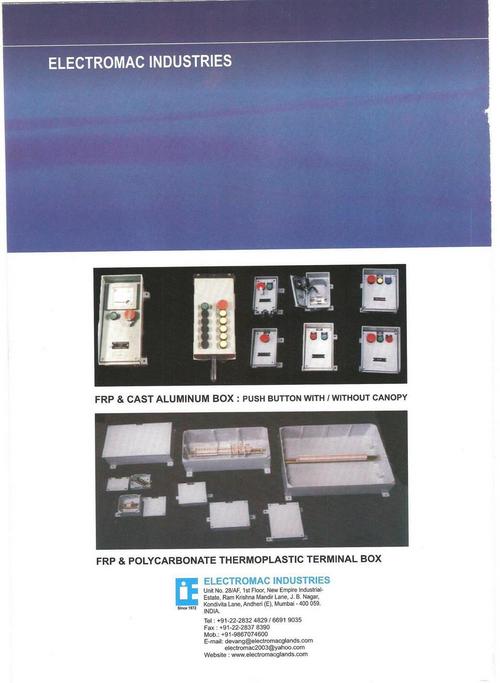

electric junction boxes

Product Details:

electric junction boxes Price And Quantity

- 1 Piece

- 1100 INR/Piece

- 1200.00 - 1500.00 INR/Piece

Product Description

An electric junction boxes is a container for electrical connections, usually intended to conceal them from sight and deter tampering. A small metal or electric junction boxes may form part of an electrical conduit wiring system in a building, or may be buried in the plaster of a wall, concealed behind an access panel or cast into concrete with only the lid showing. It sometimes includes terminals for joining wires. A similar container used for joining wires to electrical switches or sockets is called a pattress.

The term may also be used for a larger item such as a piece of street furniture. In the UK, this is sometimes called a cabinet. See Enclosure (electrical).

electric junction boxes form an integral part of a circuit protection system where circuit integrity has to be provided, as for emergency lighting or emergency power lines, or the wiring between a nuclear reactor and a control room. In such an installation, the fireproofing around the incoming or outgoing cables must also be extended to cover the electric junction boxes to prevent short circuits inside the box during an accidental fire.

Product details

|

Apparatus Standard |

Standard |

|

Size |

All |

|

Material |

FRP |

|

Brand |

Electromac |

|

Color |

All |

|

Features |

weatherproof |

Enhanced Wiring Protection for Every Environment

Our junction boxes feature sturdy powder-coated surfaces and integral end caps for comprehensive circuit protection. Rated up to IP65, they offer resistance to dust and water, making them suitable for both indoor and outdoor installation. The UV-resistant matte finish ensures lasting performance even under direct sunlight or challenging conditions.

Flexible Mounting Options and Custom Sizing

Installation is simplified with accessories like screws, brackets, and clamps included. Choose between surface or flush mounting to suit your projects needs. Available in standard square and rectangular dimensions, we also provide custom shapes and sizes, allowing adaptable integration within varied electrical distribution frameworks.

Wide Application and Compliance Standards

Designed for use in wiring protection and distribution, these boxes conform to IS 9537 and IEC 60670 standards. RoHS compliance guarantees environmental safety while injection moulded construction ensures precise tolerances. Offered by leading distributors and manufacturers in India, our junction boxes meet diverse project requirements.

FAQs of electric junction boxes:

Q: How can I select the right ingress protection rating (IP44 or IP65) for my junction box application?

A: The choice between IP44 and IP65 depends on exposure level. IP44 provides protection against splashing water and solid particles, ideal for indoor or sheltered settings. IP65 offers robust defense against dust and powerful water jets, recommended for outdoor or challenging installations.Q: What mounting types are available for these junction boxes and how do I install them?

A: You can opt for either surface mount or flush mount installation. All necessary accessories, including screws, brackets, and clamps, are supplied. For surface mounting, attach directly onto the wall; for flush mounting, recess the box into the wall and secure with brackets.Q: When is it beneficial to use a UV resistant, powder-coated junction box?

A: UV resistant, powder-coated junction boxes are ideal for environments exposed to sunlight or outdoor conditions. The matte finish prevents material degradation and maintains structural integrity, ensuring long-term reliability and performance.Q: Where can I source these electric junction boxes in custom colors or dimensions?

A: Distributors, exporters, manufacturers, and suppliers across India offer these products, with customization options for color and size upon request. Contact your local provider or the manufacturer directly to discuss specific requirements.Q: What process ensures that each junction box meets safety and compliance standards?

A: Each junction box undergoes precision injection moulding and surface treatment, adhering to IS 9537 and IEC 60670 standards. RoHS compliance further ensures environmental safety, while strict 1 mm tolerances are maintained for consistent quality.Q: How are knockouts for conduit entry used during electrical installation?

A: Knockouts are pre-designed sections in the boxs casing that can be removed to allow conduit entry. During wiring, simply punch out the required knockout and insert the conduit, maintaining a clean and organized distribution system.Q: What are the key benefits of using these junction boxes for electrical wiring protection?

A: Benefits include enhanced safety for wiring systems, versatile mounting and size options, environmental durability, and compliance with international standards. Integral end caps and accessories simplify installation, while powder-coating and UV resistance ensure lasting protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS