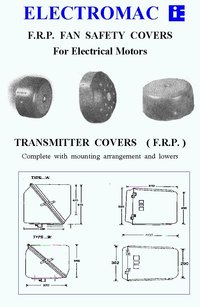

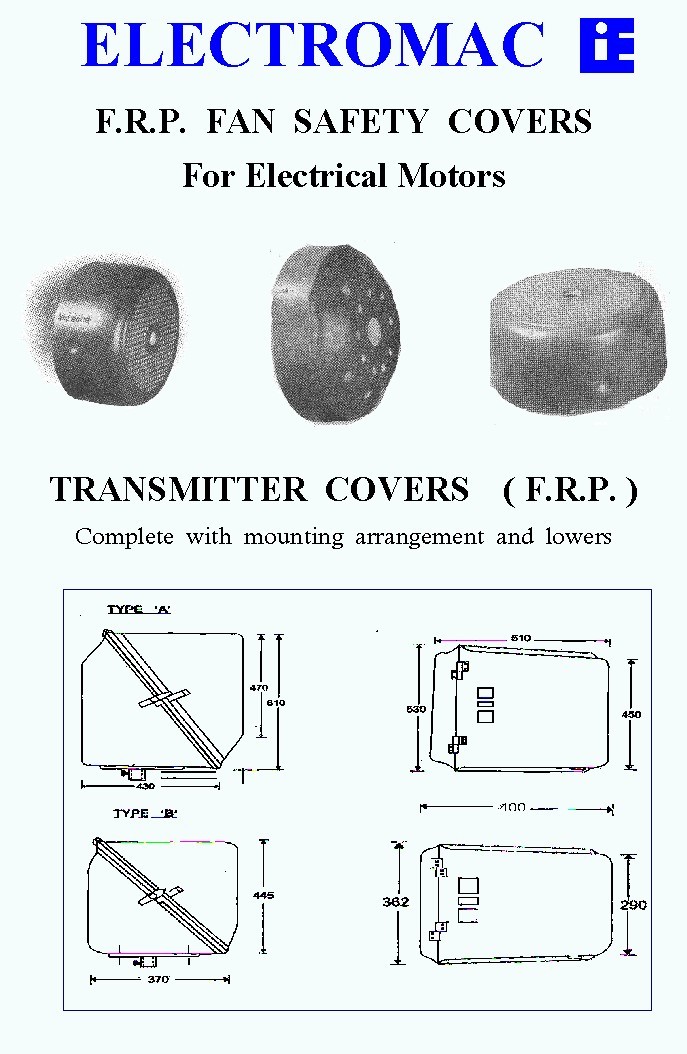

Electric Motor covers

Product Details:

- Surface Finish Smooth

- Product Type Electric Motor covers

- Application Industrial

- Protection Level IP65

- Color White

- Usage & Applications Industrial

- Size Standard

- Click to View more

Electric Motor covers Price And Quantity

- 1 Piece

- 1400.00 - 1500.00 INR/Piece

- 1500 INR/Piece

Electric Motor covers Product Specifications

- Durable

- Electric Motor covers

- Smooth

- Standard

- IP65

- White

- FRP

- Industrial

- Industrial

Electric Motor covers Trade Information

- , Gujarat, Karnataka, Dadra and Nagar Haveli, Arunachal Pradesh, Chhattisgarh, Rajasthan, Sikkim, Tamil Nadu, South India, North India, Kerala, Manipur, Daman and Diu, Punjab, Assam, Delhi, Andaman and Nicobar Islands, Nagaland, East India, Central India, West India, Mizoram, Bihar, Jharkhand, West Bengal, Odisha, Haryana, All India, Lakshadweep, Meghalaya, Andhra Pradesh, Chandigarh, Goa, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand

Product Description

gratings

Weoffer an exclusive range of premium quality FRP Motor Coversïfor offshoreapplications and corrosive chemicals. We have carved a niche as one of theoverriding Molded Fiberlass Manufacturers, based in India. Available invaried colors grating, our Fibre Reinforced Plastic Grating can be customizedas per the demand of the client. They are widely used in several sectors likepower plants, chemical plants, refineries, electroplating platform, swimmingpools, trench cover, battery racks, marine industries etc.

Advantages of are Listed Below :

- Corrosion Resistance

- High Strength

- Easy Installation

- Long Lasting Life

- Custom Panel Size

- Light Weight

- Non-Fire Retardant and Fire Retardant

- U.V. Resistant Property

Applications:

- Chemical Plant & Refineries

- Power Plants

- Swimming Pools

- Electroplating Platform

- Trench Cover

- Marine Industries

- Battery Rackes

Material:

- Isopthelic Polyster (Standard)

- Vinyle Ester - For Chemical Conditions.

ïProductï details

| Motor Part Type | Cover or Frame |

| Type Of Motor | all |

| Country of Origin | Made in India |

| Color | all |

| Brand | Electromac |

| Material Type | FRP |

ï

Enhanced Industrial Protection

These FRP electric motor covers provide IP65-rated protection, safeguarding motors from dust and water ingress in demanding industrial environments. Their durability and smooth finish extend the lifespan of equipment, minimizing downtime and maintenance costs.

Versatile Supply Network

We offer electric motor covers through multiple channelsdistribution, export, and supplycatering to wholesalers, traders, and end users across India. Our widespread network ensures availability and rapid delivery to suit diverse industrial requirements.

FAQs of Electric Motor covers:

Q: How do electric motor covers with IP65 protection enhance industrial safety?

A: IP65-rated FRP motor covers prevent dust and water penetration, reducing the risk of electrical faults and motor damage. This robust protection is crucial for maintaining operational safety and equipment reliability in harsh industrial settings.Q: What is the process for installing standard size FRP motor covers in industrial applications?

A: Installation involves placing the cover over the motor and securing it with compatible fasteners. The lightweight and rigid FRP construction simplifies handling, allowing for quick and efficient fitting by technicians.Q: When should you consider replacing electric motor covers in industrial setups?

A: Covers should be replaced if they exhibit signs of wear, cracks, or compromised sealing. Periodic inspection is recommended to ensure continued IP65 protection and optimal motor performance.Q: Where are these FRP motor covers commonly used within industrial environments?

A: They are widely employed in manufacturing units, processing plants, and workshops where electric motors are exposed to dust, moisture, or corrosive agents, ensuring dependable protection across various sectors.Q: What benefits do the smooth finish and durable construction of electric motor covers provide?

A: A smooth surface finish helps resist accumulation of contaminants, facilitating easier cleaning. The durable FRP material withstands impact and environmental stress, delivering long-term value and reduced maintenance.Q: How can distributors and traders source these electric motor covers across India?

A: Distributors and traders can contact us directly or access our extensive supply network. We offer efficient procurement, support, and timely delivery to ensure seamless availability for industrial clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free