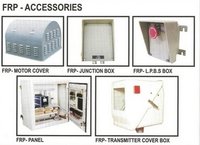

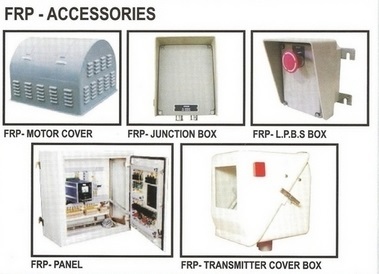

FRP Motor Cover Guards

Product Details:

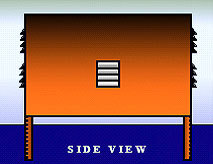

- Mounting Type Direct over motor

- Overheating Protection Indirect (Thermal Barrier)

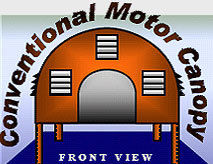

- Shape Cylindrical/Customized

- Efficiency 100% Protective Efficiency

- Humidity % Up to 95%

- Surface Finish Smooth/Glossy

- IP Rating IP55/IP65

- Click to View more

FRP Motor Cover Guards Price And Quantity

- 490.00 - 500.00 INR

- 500 INR

- 1 , , Piece

FRP Motor Cover Guards Product Specifications

- Cylindrical/Customized

- 2, 4, 6, 8

- Electric Motor Protection

- FRP (Fibre Reinforced Plastic)

- Customized as per motor

- Motor Cover Guard

- Yellow / Custom

- Smooth/Glossy

- IP55/IP65

- FRP

- 100% Protective Efficiency

- Passive/Protective

- Various (up to 90 cm length)

- Single & Three Phase

- Direct over motor

- Negligible

- Indirect (Thermal Barrier)

- 50/60 Hz

- Up to 95%

- High (Environmental and Mechanical)

Product Description

FRP motor Cover guards

Manufacturers and Fabricator of FRP motor Cover guards, in India.

The use of optimum quality materials in the manufacturing of the FRP motor Cover guards, ensures high durability, tensile strength and resistivity to adverse conditions. Various industrial sectors are placing repeated orders for the Non Corrosive frp Products, as no alternative is available in terms of quality and performance. Moreover, we are manufacturer of various types of Leak Proof frp / Guards which is available in different sizes and colors as per your requirements.

Applications

- FRP motor Cover guards on electrical motor

- Ordering Details:

- Frame Size

- Make Of Motor

- Mounting

- FLP / Non-FLP Type

- Excellent design

- Durability

- Optimum quality

- Dimensional accuracy

- Light weight

- Easy installation

Specification Sheet for FRP motor Cover guards,

| Parameters | Specifications |

| Material of Construction | FRP |

| Shape & Size | As Required |

| Type of Resin | Isopthelic Fire Retardant and Non Fire Retardant |

| Louver | Yes |

| Lifting Handle | Yes |

| Finish | Out Side Smooth Finish |

| Corrosion Resistivity | Yes |

| Moulding Proces | Hand- By - Up |

| Glass Contents | 30 to 35 % |

| Supporting | As Required at Site By FRP Angles Chennal |

| Colours | Smokegary, Yellow and As Per Your Desire |

SELECTION TABLE

| Frame Size | Horse Power | ||

|

| 3000rpm. | 1500rpm | 1000rpm |

| 80 | 1 to 1.5 | 0.75 to 1 | 0.5 to 0.75 |

| 90 | 2 to 3 | 1.5 to 2 | 1 to 1.5 |

| 100 | 4 | 3 to 4 | 2 |

| 112 | 5.5 | 5.5 | 3 |

| 132 | 7.5 to 10 | 7.5 to 10 | 4 to 7.5 |

| 160 | 15 to 25 | 15 to 25 | 10 to 15 |

| 180 | 30 | 25 to 30 | 20 |

| 200 | 40 to 50 | 40 | 25 to 30 |

| 225 | 60 | 50 to 60 | 40 |

| 250 | 75 | 75 | 50 |

| 280 | 100 to 125 | 100 to 125 | 60 to 75 |

| 315 | 150 to 230 | 150 to 230 | 100 to 195 |

| 355 | 320 to 390 | 305 to 365 | 245 to 285 |

| 400 | 440 to 520 | 440 to 520 | 380 to 435 |

For MOTORS - Please consider the next higher size of canopy.

Robust Motor Protection

Our FRP Motor Cover Guards provide high-level environmental and mechanical protection for electric motors in harsh industrial settings. Their advanced fire retardant materials and effective thermal barrier mechanisms help safeguard critical equipment from overheating, corrosion, and accidental damage, maximizing motor reliability and lifespan.

Flexible Customization Options

With a broad selection of shapes, colors, and mounting methods, these FRP covers can be tailored to fit your specific motor requirements. Customized dimensions, including options up to 90 cm in length, ensure a perfect fit for various motor types, enhancing both visual appeal and functionality while retaining excellent protective properties.

Efficient Performance and Compliance

Engineered for negligible energy consumption and 100% protective efficiency, the covers comply with IS 14856/ISO 9001 standards. Proven to reduce operational noise up to 6 dB and tolerate humidity up to 95%, they meet rigorous industrial demands for safety, durability, and environmental resistance in Indian manufacturing.

FAQs of FRP Motor Cover Guards:

Q: How does the FRP Motor Cover Guard protect electric motors from environmental factors?

A: The cover guards are made from fibre reinforced plastic with high fire retardancy (Class F), excellent UV stability, and superior chemical resistance, shielding motors against dust, corrosion, humidity (up to 95%), and mechanical impacts.Q: What customization options are available for FRP Motor Cover Guards?

A: You can customize the guards shape, color, dimensions, and mounting type to suit your motors specific requirements. Options include cylindrical or custom shapes, various sizes (up to 90 cm), and multiple mounting configurations.Q: When should I replace an FRP Motor Cover Guard?

A: With a service life of up to 10 years under normal conditions, replacement is recommended if the guard shows signs of significant wear, cracking, or loss of protective efficiency due to extreme operating environments.Q: Where can FRP Motor Cover Guards be used?

A: These guards are ideal for industrial, commercial, or outdoor motor applications where environmental protection, fire safety, and mechanical shielding are important, especially in settings that demand compliance with IS 14856/ISO 9001 standards.Q: What is the process for ordering a customized FRP Motor Cover Guard?

A: Start by specifying your motor type, desired dimensions, color, and mounting preferences. A supplier in India will manufacture the cover according to your requirements, adhering to quality and compliance standards.Q: How do FRP Motor Cover Guards contribute to noise reduction?

A: They are engineered to reduce operational noise by up to 6 dB, helping create quieter work environments and supporting occupational health and safety objectives in manufacturing plants or other facilities.Q: What are the benefits of using FRP material for motor cover guards?

A: FRP offers high mechanical strength, fire retardancy, chemical resistance, and excellent durability, making it an ideal choice for long-lasting motor protection with minimal energy consumption and reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free