ढाला हुआ झंझरी

500 आईएनआर

उत्पाद विवरण:

- जीएसएम Varies (Typically 1200–1800 gsm depending on grid and thickness)

- ऊष्मीय चालकता Low, approximately 0.25 W/mK

- शेप Rectangular Grating/Grid

- मोटाई 25 mm, 30 mm, 38 mm, 50 mm (Standard options)

- कोटिंग का प्रकार UV Resistant/Resin Coating

- उपयोग/अनुप्रयोग Corrosive Environments, Electrical Isolation, High Strength Flooring

- घनत्व ग्राम प्रति घन सेंटीमीटर (g/cm3)

- अधिक देखने के लिए क्लिक करें

X

ढाला हुआ झंझरी मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

ढाला हुआ झंझरी उत्पाद की विशेषताएं

- 1220 mm x 3660 mm x 38 mm (Custom sizes available)

- Rectangular Grating/Grid

- Corrosive Environments, Electrical Isolation, High Strength Flooring

- Varies (Typically 1200–1800 gsm depending on grid and thickness)

- Low, approximately 0.25 W/mK

- Industrial Walkways, Platforms, Stairs, Chemical Plants, Marine Environments

- Molding Process/Fiberglass Molded

- Fiberglass Reinforced Plastic (FRP)

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- UV Resistant/Resin Coating

- 25 mm, 30 mm, 38 mm, 50 mm (Standard options)

उत्पाद वर्णन

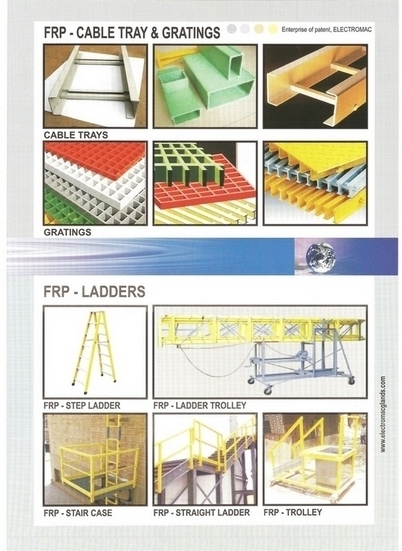

molded grating

We offer an exclusive range of premium quality molded grating for offshore applications and corrosive chemicals. We have carved a niche as one of the overriding Molded Fiberlass Grating Manufacturers, based in India. Available in varied colors grating, our Fibre Reinforced Plastic Grating can be customized as per the demand of the client. They are widely used in several sectors like power plants, chemical plants, refineries, electroplating platform, swimming pools, trench cover, battery racks, marine industries etc.

Advantages of molded grating are Listed Below :

- Corrosion Resistance

- High Strength

- Easy Installation

- Long Lasting Life

- Custom Panel Size

- Light Weight

- Non-Fire Retardant and Fire Retardant

- U.V. Resistant Property

Applications :

- Chemical Plant & Refineries

- Power Plants

- Swimming Pools

- Electroplating Platform

- Trench Cover

- Marine Industries

- Battery Rackes

Material :

- Isopthelic Polyster (Standard)

- Vinyle Ester - For Chemical Conditions.

Superior Safety and Versatility

Engineered with a focus on safety, our molded gratings provide a slip-resistant walking surface and high mechanical strength, even in corrosive or marine environments. The products electrical isolation properties add another layer of protection, making it essential for chemical plants, platforms, or high-strength flooring needs.

Customizable to Your Project Needs

With multiple color optionslight grey, green, yellow, or customalongside an array of thicknesses and sizes, our grating is adaptable to your industrial requirements. The availability of fire retardant and UV resistant coatings ensures the grating stands up to severe outdoor exposure while maintaining its original appearance and function.

FAQs of molded grating:

Q: How is the molded fiberglass grating installed?

A: Molded fiberglass grating can be installed using a variety of methods, including clips, bolts, or custom fixings, depending on site requirements. These methods ensure secure attachment to supporting structures for both safety and stability.Q: What are the main benefits of using FRP molded grating in industrial or corrosive environments?

A: The primary advantages include high load capacity, excellent resistance to corrosion and UV rays, electrical insulation, low maintenance, and easy cleaning. These features make FRP gratings particularly suitable for platforms, walkways, stairs, and settings exposed to harsh chemicals or marine conditions.Q: Where can molded FRP grating be used?

A: This product is widely applied in industrial walkways, platforms, stairs, chemical plants, and marine environments. Its durability, slip resistance, and electrical isolation properties make it suitable for use wherever safety and longevity are prioritized.Q: What customization options are available for molded grating colors and sizes?

A: Customers can choose from standard colors (light grey, green, yellow) or request customized shades to match their facility branding or visibility needs. Dimensions and bar spacing can also be tailored to project-specific requirements, ensuring an exact fit.Q: When should I consider selecting the fire retardant grade option?

A: The fire retardant grade, available upon request and conforming to ASTM E84 Class 1, is recommended for environments where fire risk is a concern, such as high-temperature industrial settings or areas regulated for fire protection.Q: What thickness options are offered for molded grating, and how do I choose the right one?

A: Standard thicknesses include 25 mm, 30 mm, 38 mm, and 50 mm. The choice depends on the expected load and application: heavier loads or longer spans typically require thicker grating for optimal support and safety.Q: How does the products UV resistance benefit long-term outdoor usage?

A: Excellent UV resistance, provided by a resin coating, protects the grating from sunlight degradation, preserving its strength, color, and performance even after prolonged outdoor exposure. This ensures longer product life and reduces maintenance costs.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

संपर्क करें

संपर्क करें जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें