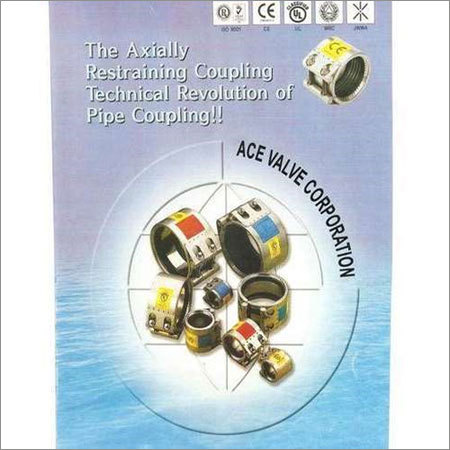

पाइप कपलिंग

उत्पाद विवरण:

- सहनशीलता मिलीमीटर (mm)

- टेन्साइल स्ट्रेंथ मेगापास्कल (एमपीए)

- कनेक्शन का प्रकार Female

- व्यास मिलीमीटर (mm)

- फ्लेक्सिबिलिटी Rigid

- यील्ड स्ट्रेंथ 180 MPa

- सीलिंग टाइप Rubber Gasket

- अधिक देखने के लिए क्लिक करें

पाइप कपलिंग मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

पाइप कपलिंग उत्पाद की विशेषताएं

- मिलीमीटर (mm)

- मिलीमीटर (mm)

- मिलीमीटर (mm)

- Rubber Gasket

- Joining Pipes

- Grade A

- 16 Bar

- Silver

- मेगापास्कल (एमपीए)

- मिलीमीटर (mm)

- Zinc Coated

- मिलीमीटर (mm)

- Rigid

- 180 MPa

- मिलीमीटर (mm)

- Female

- NPT

उत्पाद वर्णन

Backed by a modernized infrastructure facility, we are able to provide the clients with a wide range of Pipe Couplings. These products are used in different pipe fittings for securing two ends of pipes together. Tested by our team of skilled quality personnel, we are able to offer an qualitative range of these products to the clients. Pipe Couplings are packed in damage and tamper proof packaging so as to ensure their safe transportation.

Other details:

It is a pleasure to know your distinguished company. it is pertinent to mention that ACE, Korea is represented in India by Electromac Industries this is an introductory letter from our end with an aim to introduce ace couplings to your company & initiate mutually beneficial business association.

ACE, is fully capable of integrating the complete pipe, grip ring, multi-flex couplings requirements of our clients and offer to them as a comprehensive package immensely benefiting the existing buyers / clients.

Product; :- Leak Proof Couplings for Repair, Maintenance, as listed below range:

- Pipe couplings

- Grip ring couplings

- Multi-flex couplings

- Repair clamp double lock couplings

- Repair clamp spread - opening couplings

- Repair clamp hinged - opening couplings

The various sophisticated and complex valves supplied by us are based on the requirements projected by our buyer and they are made from sus 304, sus 316 etc conforming to rigorous international standards (api & ansi) with adequate capability to withstand high pressure applications as demanded by our esteemed buyers across the world.

ACE, Pipe Couplings produce a fast and flexible joint which lengthens the lifetime of the piping and lowers maintenance costs. Pipe couplings are used every where there are pipes. They can quickly join even piping of different materials. The flexible joints, requiring no special tools, are completely tight and durable. They also allow a diameter difference and a substantial inclined deviation between pipe diameters.

For shipbuilding, Offshore

For water and gas supplies

For building construction and civil engineering

For power plants

For machinery, design work

For industrial plants. Plant maintenance.

Superior Material and Construction

Constructed from high-grade cast iron and protected with a galvanized zinc coating, these pipe couplings offer impressive tensile strength of 260 MPa and yield strength of 180 MPa. The cylindrical design and 5 mm wall thickness ensure structural integrity, while the silver finish provides lasting resistance to corrosion, suitable for both indoor and outdoor settings.

Easy Installation and Reliable Sealing

The couplings feature a socket weld connection and NPT female threads, enabling straightforward assembly using industry-standard methods. Fitted with a durable rubber gasket, they provide a secure and leak-resistant seal, making installation hassle-free and reducing downtime in pipeline projects.

FAQs of Pipe Couplings:

Q: How are these pipe couplings installed on pipelines?

A: These couplings are designed for socket weld installation with NPT female threads and a rubber gasket seal. Simply align the plain ends of the pipes, insert them into the coupling, and tighten to ensure a robust, leak-proof connection.Q: What benefits does the galvanized and zinc-coated surface provide?

A: The galvanized and zinc-coated finish offers excellent protection against corrosion, ensuring long-term performance in water, oil, and gas pipeline applications, even in harsh or outdoor environments.Q: When should I use these couplings for my pipeline system?

A: These couplings are ideally used during the construction or maintenance of water, oil, or gas pipelines where high corrosion resistance, mechanical strength, and reliable sealing are needed. Their easy installation makes them suitable for both new builds and repairs.Q: Where can these pipe couplings be used effectively?

A: They are designed for use in industrial, residential, and commercial pipeline systems across water, oil, and gas networks, particularly where durability and high operating pressure are required.Q: What is the maximum operating pressure tolerated by these couplings?

A: These couplings are rated to handle a maximum operating pressure of 24 Bar and a rated pressure of 16 Bar, making them suitable for demanding pipeline operations.Q: How do I ensure proper alignment given the 1 mm tolerance?

A: During installation, use standard measuring tools to ensure pipes align within 1 mm of the couplings dimension for optimal sealing and mechanical performance.Q: What advantages does the fixed bend radius and rigid flexibility offer?

A: The fixed bend radius and rigid design maintain the structural integrity of the pipeline, making these couplings suitable for applications where minimal movement and maximum strength are necessary.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

संपर्क करें

संपर्क करें जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें